Our Services

Engineering and Analysis

We offer comprehensive additive manufacturing services, leveraging expert engineering and cutting-edge tools for design optimization, structural analysis, and performance evaluation. Our mission is to provide insights and tools for informed decision-making to meet your engineering goals.

- Engineering Services

- Analaysis Services

Tab 1

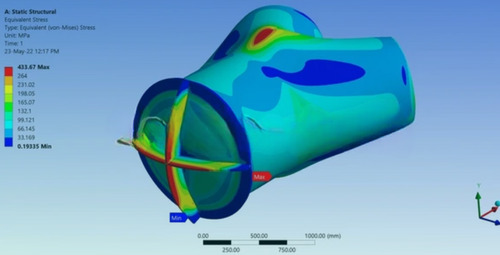

Simulation & Analysis

Our Simulation & Analysis Service uses state-of-the-art tools to optimize designs and ensure structural integrity in additive manufacturing. We ensure that your 3D-printed components meet your expectations, saving you time resources, and production. Trust us for accuracy and efficiency to take your additive manufacturing projects to the next level.

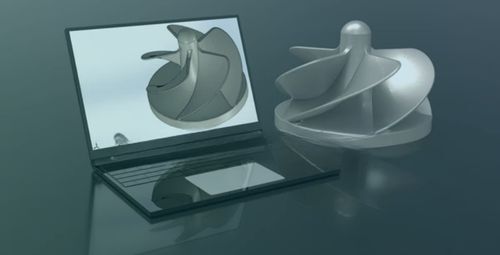

Computer Aided Design

Our CAD Service is crucial for successful additive manufacturing. Skilled professionals use advanced software to create precise 3D models, whether from scratch or refining existing designs. With tailored solutions, our CAD expertise ensures efficiency and quality from inception to production.

Benchmark

In the context of additive manufacturing, a benchmark typically refers to a standard or a set of standards used to assess and measure the performance, capabilities, and quality of 3D printing processes, materials, or systems. Our Benchmark Service sets the standard for excellence in additive manufacturing. With our expertise, your projects consistently deliver outstanding results, maintaining a competitive edge.

Optimization

Our Optimization Service maximizes the potential of additive manufacturing. Using advanced algorithms, we fine-tune designs and processes for optimal performance. Tailored solutions address specific goals, such as increased strength or reduced weight. We empower you to achieve high-quality results while minimizing waste and production costs for a competitive edge.

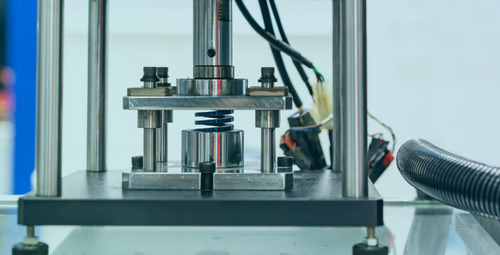

Test and Validation

Our Test and Validation Service is essential for the reliability of additive manufacturing. We rigorously test 3D-printed components using state-of-the-art equipment to meet industry standards. Our meticulous approach ensures confidence in consistent, high-quality results for your projects, making us your trusted partner for success.

Reverse Engineering

Our Reverse Engineering approach unlocks additive manufacturing potential by creating precise digital models from physical parts. Whether you need to recreate unique components or improve existing designs, our solutions cater to a wide range of needs. With our expertise, we bridge the gap between the physical and digital worlds, enabling you to harness the power of additive manufacturing with confidence and precision.

Prototype

Our Prototype Service swiftly transforms your concepts into high-quality prototypes. Using cutting-edge technology, our expert team ensures rapid testing and refinement without compromising precision. Whether exploring new concepts or refining existing ones, our tailored solutions keep you ahead in the additive manufacturing realm.

Tab 2

Linear & Non-Linear Structural Analysis

Our Structural Analysis Service ensures the strength and reliability of additive manufacturing projects. Through advanced techniques, we assess and optimize the structural integrity of 3D printed components, aiming to boost confidence in designs and maximize quality while minimizing risks.

Optimization & DOE

Our Optimization and DOE Service improves additive manufacturing by enhancing production methods. Using cutting-edge techniques, we tailor solutions for specific goals, unlocking the full potential and ensuring efficiency, consistency, and quality across projects.

Welding

Our Welding Service ensures the precise joining of additively manufactured metal components. Skilled welders use advanced techniques for strong, flawless connections. Tailored solutions are provided for assembly or repair with a commitment to quality. This enhances structural integrity, meeting high standards for additive manufacturing projects.

Fatique

Our Fatigue Test Service ensures the durability of additive manufacturing components through rigorous tests under cyclic loading. With advanced equipment, our team provides valuable insights into the endurance and lifespan of 3D printed parts, ensuring confidence in long-term project performance.